Raw Material

Wire with high-carbon chrome bearing coil (100Cr6) and carbon content of 0.95 ~ 0.98%. It has outstanding wear resistance.

PRIDE OF QUALITY PARKWON STEEL BALL

Wire with high-carbon chrome bearing coil (100Cr6) and carbon content of 0.95 ~ 0.98%. It has outstanding wear resistance.

| Item | Frequency |

|---|---|

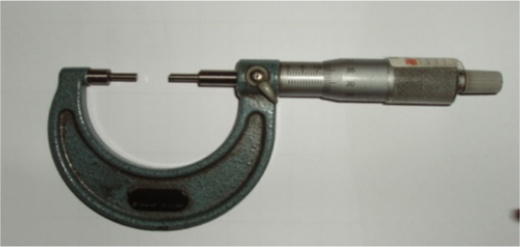

| Wire diameter deviation | Once/coil |

| Exterior | Once/coil |

| Structure, Chemical components | Once/6 months |

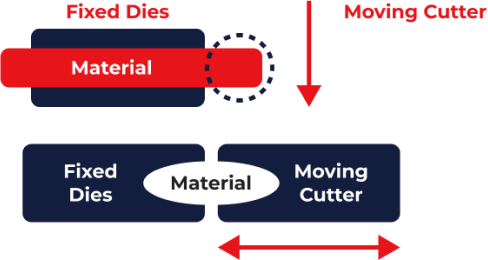

Process of cutting the wire according to the standard and shaping with dies to form the sphere shape

| Item | Frequency |

|---|---|

| External diameter inspection | once/lot |

| Visual inspection | once/lot |

| acid treatment test | once/lot |

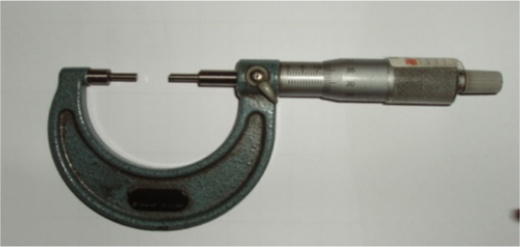

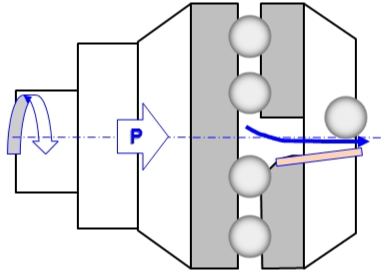

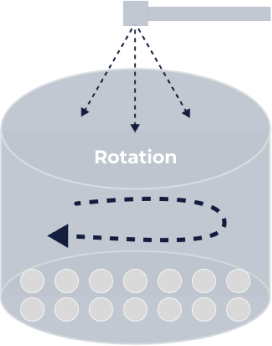

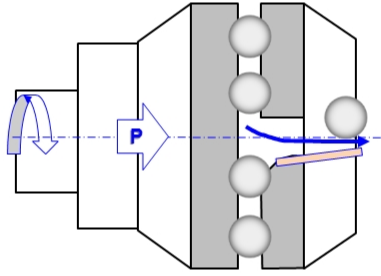

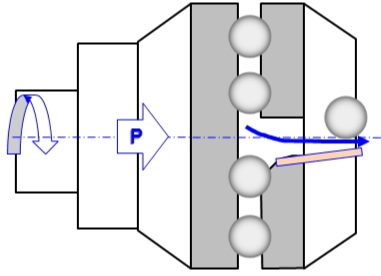

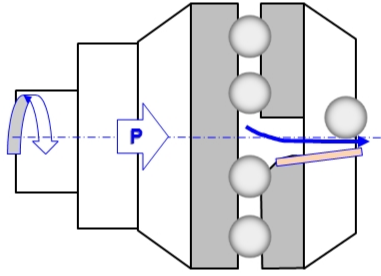

Headed ball is processed on the grinding plate made from special cast iron with two grooves rotating at high speed. In this process, the heading impression on lateral and axial directions are removed and processed into the diameter needed for the ball.

| Item | Frequency |

|---|---|

| Visual inspection | once/lot |

| External diameter inspection | once/1hr |

Removing the oil on the ball before heat treatment by rinsing with water.

| Item | Frequency |

|---|---|

| Appearance | once/lot |

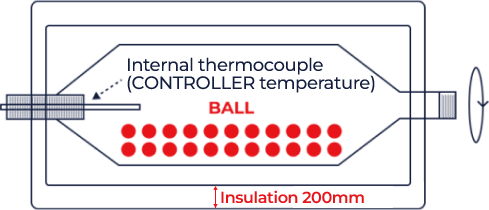

Ball is processed in the heat treatment furnace for quenching and tempering. Strength and durability are obtained in this process.

| Item | Frequency |

|---|---|

| Hardness test | once/lot |

| Microstructure | once/lot |

Ball is inserted repeatedly between the grinding plate with two grooves rotating at high pressure until the desired diameter is reached.

| Item | Frequency |

|---|---|

| Visual inspection | once/lot |

| External diameter inspection | once/1hr |

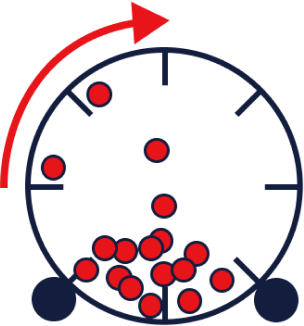

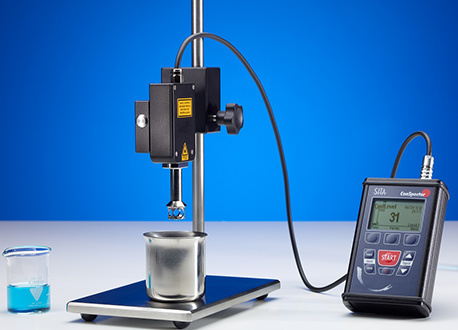

Balls collide against each other to make the surface hard for improved resistance against dents, prevention of surface defect and bearing lifespan.

Tumbling process generates minus residual stress to satisfy customer requirements.

| Item | Frequency |

|---|---|

| Rockwell Hardness Tester | once/lot |

Just like the grinding process, grinding plates made with different materials are used in each process until the desired diameter is reached, and the accuracy of ball’s shape is improved.

| Item | Frequency |

|---|---|

| Appearance | once/lot |

| Dimension | once/2hr |

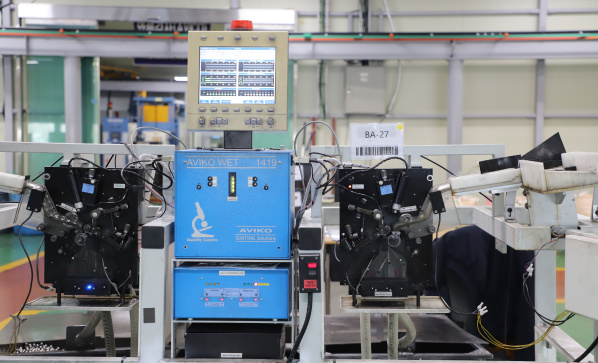

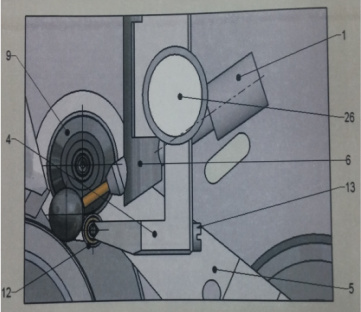

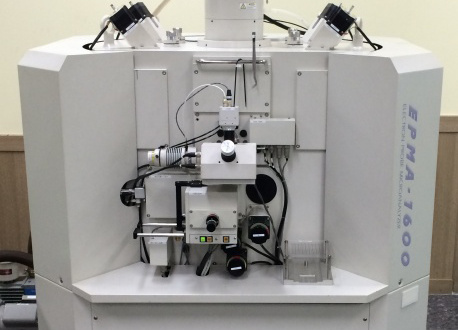

AVIKO is an automatic machine to detect surface defects of bearing ball. It is an ECT crack inspection equipment that detects defects of 750μm(L) x 750μm(W) x 50μm(H) in size.

| Item | Frequency |

|---|---|

| EOT, EVT, ECT | 100% |

Microchips on the steel ball surface from lapping process are removed using ultrasound oscillator to improve cleanliness of the ball.

| Item | Frequency |

|---|---|

| Appearance | once/lot |

| Dimension | once/2hr |

Microchips on the steel ball surface from lapping process are removed using ultrasound oscillator to improve cleanliness of the ball.

| Item | Frequency |

|---|---|

| Cleanliness Test | once/month |

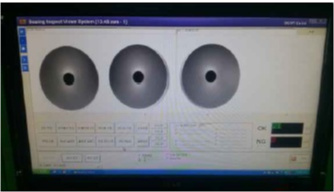

Vision is an automatic machine to detect defects on the surface of bearing ball, and can detect surface defect of 200㎛ or more.

| Item | Frequency |

|---|---|

| Appearance | 100% |

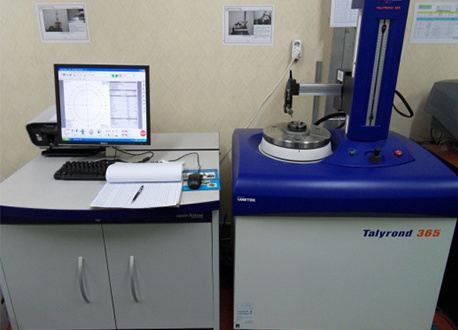

| Item | Frequency | Item | Frequency |

|---|---|---|---|

| Gauge | N=5/lot | Variation of ball lot diameter | N=5/lot |

| Variation of ball diameter | N=5/lot | Deviation from spherical form | N=5/lot |

| Surface roughness | N=5/lot | Hardness | N=5/lot |

| Waviness | N=5/lot | Breaking loads | N=5/6month |

| Grinding burn | N=10/quarter | Microstructure, A.G.S, Carbide banding | N=2/quarter |

| Retained Austenite, Residual Stress | N=2/quarter | Dimensional stability | N=25/quarter |

| Retained magnetism | N=10/quarter | Residual contamination | N=standard/quarter |

Finished products are stored until shipping.

| Item | Frequency |

|---|---|

| Difference Ball | 100% |

| Quantity | All |

Finished products are stored until shipping.